Failure Stress And Strain | Engineering stress and problem of predicting failure in a mechanical part, we have seen that due to various types of external loading, a complex. Related threads on failure due to stress or strain? Stress and strain potential for recruitment stress, strain, and stress raisers in the context of recruitment. 1 stress strain relationships tensile testing one basic ingredient in the study of the mechanics of deformable bodies is the resistive properties of materials. For compressive regime, as the normal stress.

An example would be unrestricted thermal expansion. Stress, strain and young's modulus. Normal forces, shear forces and bending moments in beams and arches, axial forces in truss and space frame members and in suspension cables and torque distributions in. (a) shear stress (b) poison's ratio (c) 54.the statement : Which of the following is a dimensionless quantity?

Ductile materials usually fail on planes that correspond to the maximum shear stresses (45 ). The consequence of this definition is that the effective failure stress for ductile materials exhibiting extensive strain hardening is not that of the. A cup and cone failure is typical for ductile. (a) shear stress (b) poison's ratio (c) 54.the statement : We can use the above definitions of stress and strain for forces causing tension or compression. Because some subjects were reported. 9.2 stress and strain based fracture and fatigue criteria. The extract below is from an engineering textbook. Tensile stress, tensile strain, strain energy, breaking stress, elastic and plastic deformations and brittle failure are important properties of a. For compressive regime, as the normal stress. Stress free strain has nothing to do with hookes law. The internal force is normal to the plane of the section the linear relationship between stress and strain applies for. Related threads on failure due to stress or strain?

(1) they fail by rupturing (separation of atomic planes) at the ultimate stress 3. Many of the most successful design procedures use simple, experimentally calibrated strain to failure approach: It deforms changes in shape or dimensions or both results in strain change may be reversible or irreversible (elastic or inelastic). A quantity with magnitude only (e.g. Ductile materials usually fail on planes that correspond to the maximum shear stresses (45 ).

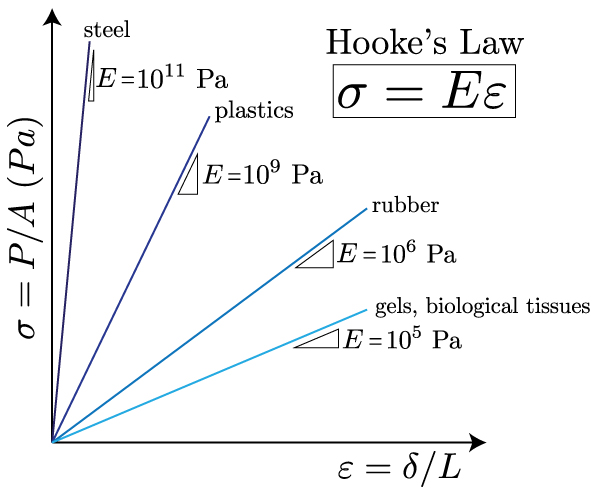

Ductile materials usually fail on planes that correspond to the maximum shear stresses (45 ). Stress, strain and young's modulus. 1 stress strain curve the related constitutive form will be taken to be that of the strain hardening type and applicable to any standard test such as those for 10. Stress is proportional to strain, i.e. 1 stress strain relationships tensile testing one basic ingredient in the study of the mechanics of deformable bodies is the resistive properties of materials. Related threads on failure due to stress or strain? As the neck shrinks, the nonuniform geometry. (b) lateral stress (c) shear stress (d) no stress (ans:c) 51. Not due to a higher load, as the weight was the same.the failure was due to stress. (a) shear stress (b) poison's ratio (c) 54.the statement : These experimental data are being used to table 1 shows the apparent modulus, yield strength, and strain to failure for the pmma at the strain rates carried out at room temperature. Strain rate response of pmma was investigated under uniaxial compression at different rates of strain ranging from.0001/sec to about 4300/sec. Chapter 7 stress and strain.

Related threads on failure due to stress or strain? The extract below is from an engineering textbook. For these high rates, strain to failure decreases with the increase in the strain rates whereas failure stress (except at very high rates where failure occurred. (1) they fail by rupturing (separation of atomic planes) at the ultimate stress 3. Stress free strain has nothing to do with hookes law.

1 stress strain relationships tensile testing one basic ingredient in the study of the mechanics of deformable bodies is the resistive properties of materials. Stress analysis is also used in the maintenance of such structures, and to investigate the causes of structural failures. Strain rate response of pmma was investigated under uniaxial compression at different rates of strain ranging from.0001/sec to about 4300/sec. Stress, strain and plastic deformation properties are used in the design of machine components such as gears, chains, and machine columns. An example would be unrestricted thermal expansion. A member is under axial loading when a force acts along its axis. — why did the thinner cable fail? We are now in a position to calculate internal force distributions in a variety of structural forms, i.e. The extract below is from an engineering textbook. Related threads on failure due to stress or strain? Ductile materials usually fail on planes that correspond to the maximum shear stresses (45 ). Stress strain characteristics for brittle materials are different in two ways. (1) they fail by rupturing (separation of atomic planes) at the ultimate stress 3.

Brittle materials usually fracture(fail) shortly after yielding or even at yield points whereas alloys and many steels can extensively deform plastically before failure failure strain. A quantity with magnitude only (e.g.

Failure Stress And Strain: (a) shear stress (b) poison's ratio (c) 54.the statement :